317L Stainless Steel Buttweld Elbow | ASTM A403 Stainless Steel WP317L 90 Degree Elbow | ASTM A403 WP317L 45° Elbow | ASTM A403 WP317L 180° Elbow | SS 317L Long Radius Elbow | ANSI B16.9 WP317L Stainless Steel SR Elbow | WP317L Stainless Steel LR Elbow.

Stainless Steel 317L Pipe Fittings, WP317L SS 45 degree Elbow, SS 317L Equal Tee Manufacturer in India.

Neelkamal Alloys LLP is a known manufacturer and exporter of Gr. 317L Pipe Fittings, which is manufactured using finest quality stainless steel. We are a renowned organization involved in offering a premium quality collection of Grade 317L Elbow to our clients, which is highly developed technology by our experts. Further, we offer this ASTM A403 WP317L Tee at market leading price, where the product sizes are client specified. Furthermore, offered ASME A403 WP317L Equal Cross is also available with us in different sizes to meet specific demand of our clients. The offered A403 317L Reducer are also made as per the clients’ specifications in order to meet their requirements. Precisely designed, ASME A403 WP317L Short & Long Radius Bend offered by us are high on quality and finish. The following is a range of improved properties in A403 317L Stub End (as compared to carbon steels): strength, hardness, toughness, wear resistance, corrosion resistance, hardenability, and hot hardness.

Buy Grade 317L 90 deg. Elbow, SS WP317L Short Radius Elbow, DIN 1.4438 Stub End, ASTM A403 WP317L Cross Supplier in Mumbai, India.

Quick Section Links

- What is Stainless Steel 317L Pipe Fittings?

- ASME B16.9 Stainless Steel 317L Butt weld Fittings Specifications

- ANSI B16.9 Stainless Steel 317L Buttweld Pipe Fittings Forms & Availability

- Types of Stainless Steel 317L Buttweld Pipe Fittings

- ASTM A403 WP317L Stainless Steel Buttweld Pipe Fittings Equivalent Grades

- ASTM A403 WP317L Stainless Steel Pipe Fittings Price List

- 317L Stainless Steel Buttweld Pipe Fittings Chemical Composition

- Stainless Steel 317L Buttweld Fittings Mechanical Properties

- Other Types of Grade 317L Stainless Steel Pipe Fittings in Stock

To achieve some of these improved properties, Stainless Steel 317L Reducing Tee Pipe Fittings may require heat treating. Stainless Steel 317L Concentric Reducer Pipe Fittings has some prominent features to offer such as excellent finish, durable, robust construction, dimensional accuracy, high resistance to rusting, and more. We offer a comprehensive range of Stainless Steel 317L Reducing Cross Pipe Fittings, which is available in different specifications, dimension and materials.

Dimensional Standards For Stainless Steel Pipe Fittings

- American Standard Fittings (ANSI/ASME/AWWA)

- European Standard Fittings (EN)

- German Standard Fittings (DIN)

- British Standard Fittings (BS)

- Japanese Standard Fittings (JIS)

- MSS Standard Fittings (MSS-SP)

- Petroleum Standard Fittings (API)

- South African Standard Fittings (SABS / SANS)

- Russian Standard Fittings (GOST)

Material Testing of Stainless Steel Pipe Fittings

- Mechanical Testing Such as Tensile of Area

- Chemical Analysis – Spectro Analysis

- Hardness Test

- Positive Material Identification – PMI

- Chemical Analysis – Spectro Analysis

- Testing

- Micro and MacroTest

- Flattening Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

Documentation of Stainless Steel Pipe Fittings

- Commercial Invoice which includes HS Code

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Packing List including net weight and gross weight, number of boxes, Marks and Numbers

- Raw Material Test Reports

- Fumigation Certificates

- Material Traceability Records

- Raw Material Test Reports

- Quality Assurance Plan (QAP)

- Material Traceability Records

- Heat Treatment Charts

- Quality Assurance Plan (QAP)

- Test Certificates certifying NACE MR0103, NACE MR0175

- Heat Treatment Charts

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- NABL approved Laboratory Test Reports

- Form A for the purposes of the Generalized System of Preferences (GSP)

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

ASME B16.9 Stainless Steel 317L Butt weld Fittings Specifications

| Specifications | ASTM A403 / ASME SA403 |

|---|---|

| Pipe Fittings size | Seamless Stainless Steel Butt Weld Fittings: 1/2" - 10" Welded Stainless Steel Butt Weld Fittings: 1/2" - 48" |

| Pipe Fittings Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Pipe Fittings Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Pipe fittings Types | Seamless / ERW / Welded / Fabricated |

| Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011, DN15-DN1200 BS : BS4504, BS4504, BS1560, BS10 JIS : JIS B2311, JIS B2312, JIS B2313, JIS B2316 GOST : GOST 17375, GOST 17376, GOST 30753, GOST 17378, GOST 17379, GOST 17380 EN: EN10253-1, EN10253-2 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Pipe Fittings Elbow | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Pipe Fittings Manufacturing process | Push, Press, Forge, Cast, etc. |

| Pipe Fittings Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Specialized manufacturer of | 90º Elbows, Couplings, Reducers, Inserts, Caps, Nipples, 45º Elbows, Tees, Crosses, Equal Tees & Reducing Tees |

| Buttweld Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Pipe Fittings uses & application | |

| Material Test Certificates (MTC) for Stainless Steel 317L Pipe Fittings as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Stainless Steel 317L Buttweld Pipe Fittings Standards

| Standard | Description |

| ASTM A403/A403M | Wrought austenitic stainless steel piping fittings. |

| AS 2129 | Flanges for pipes, valves and fittings |

| ANSI B16.9 | Factory-made wrought steel butt-welding fittings. |

| ANSI B16.25 | Butt-welding ends. |

| MSS SP43 | Wrought stainless steel butt-welding fittings. Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

| BS3799 | Specification for Steel Buttweld Pipe Fittings, screwed and Socket-welding for the petroleum industry |

| ANSI – B 16.9 ASTM A403 – ASME SA403 |

‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ |

| API 590-605 ASME B16.9 |

‘Factory-Made Wrought Buttwelding Fittings’ |

| ASME B16.25 | ‘Buttwelding Ends’ |

| ASME B16.28 | ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ |

Call +91- 22- 66362225 / +91- 22- 66662225 OR

Email us at sales@neelkamalsteels.com for quick response

ANSI B16.9 Stainless Steel 317L Buttweld Pipe Fittings Forms & Availability

| Products | Size | |

| SS 317L Elbows – Long Radius | SS 317L Stub Ends | Sizes 1/2″ – 48″ |

| SS 317L Elbows – Short Radius | SS 317L Crosses | |

| SS 317L Reducing Elbows | SS 317L Reducing Cross | |

| SS 317L 45° Elbows | SS 317L 180° LR Return Bends | |

| SS 317L Tees | SS 317L 180° SR Return Bends | |

| SS 317L Equal Tees | SS 317L Pipe Bends / Piggable Bends | |

| SS 317L Reducers | SS 317L 3D Elbow | |

| SS 317L Concentric Reducers | SS 317L Steel Pipe Nipples | |

| SS 317L Eccentric Reducers | SS 317L 5D Elbow | |

| SS 317L 3D Elbow | SS 317L End Caps | |

| SS 317L 1D Elbow | SS 317L Seamless Pipe Fittings | |

| SS 317L Welded Fittings | SS 317L Lap Joint Stub Ends | |

Types of Stainless Steel 317L Buttweld Pipe Fittings

SS 317L Elbow

SS 317L Tee

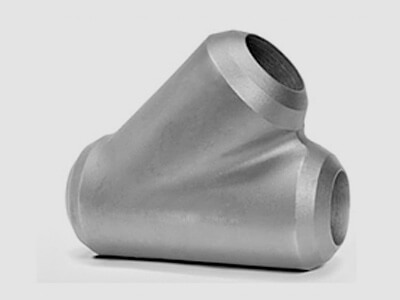

317L Stainless Steel Buttweld Tee | ASTM A403 Stainless Steel WP317L Equal Tee | ASTM A403 WP317L Unequal Tee | ASTM A403 WP317L Reducing Tees | ANSI B16.9 WP317L Stainless Steel Buttweld Tees.

SS 317L Cross

317L Stainless Steel Buttweld Cross | ASTM A403 Stainless Steel WP317L Equal Cross | ASTM A403 WP317L Unequal Cross | ASTM A403 WP317L Reducing Cross | ANSI B16.9 WP317L SS Buttweld Cross.

SS 317L Reducer

317L Stainless Steel Buttweld Reducer | ASTM A403 Stainless Steel WP317L Eccentric Reducer | ASTM A403 WP317L Concentric Reducer | ASTM A403 WP317L Reducer | ANSI B16.9 WP317L SS Buttweld Reducer.

SS 317L Stub End

317L Stainless Steel Buttweld Stub End | ASTM A403 Stainless Steel WP317L Long Stub End | ASTM A403 WP317L Short Stub End | ASTM A403 WP317L Lap Joint Stub End | ANSI B16.9 WP317L Stainless Steel Buttweld Stub End.

SS 317L Pipe End Cap

317L Stainless Steel Buttweld Pipe End Cap | ASTM A403 Stainless Steel WP317L Pipe End Cap | ASTM A403 WP317L Pipe Cap | ASTM A403 WP317L End Cap | ANSI B16.9 WP317L Stainless Steel Buttweld Pipe End Cap.

SS 317L Pipe Bend

317L Stainless Steel Buttweld Pipe Bend | ASTM A403 Stainless Steel WP317L U Bend | ASTM A403 WP317L Piggable Bends | ASTM A403 WP317L Long Radius Bend | ANSI B16.9 WP317L Stainless Steel Buttweld 180D Pipe Bend.

SS 317L Pipe Nipples

317L Stainless Steel Buttweld Pipe Nipple | ASTM A403 Stainless Steel WP317L Pipe Nipple | ASTM A403 WP317L Barrel Nipple | ASTM A403 WP317L Pipe Nipples | ANSI B16.9 WP317L Stainless Steel Buttweld Barrel Nipple.

SS 317L Lateral Tee

317L Stainless Steel Buttweld Lateral Tee | ASTM A403 Stainless Steel WP317L Lateral Tee | ASTM A403 WP317L Lateral Tee | ASTM A403 WP317L Lateral Tee | ANSI B16.9 WP317L Stainless Steel Buttweld Lateral Tee.

ASTM A403 WP317L Stainless Steel Buttweld Pipe Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

ASTM A403 WP317L Stainless Steel Pipe Fittings Price List

Contact us or click on request a quote button to get our competitive prices for 317L Stainless Steel Buttweld Fittings. Neelkamal Alloys LLP maintain the large inventory of high quality ASTM A403 WP317L Stainless Steel Buttweld Fittings for sale to our clients throughout globally.

317L Stainless Steel Buttweld Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

Stainless Steel 317L Buttweld Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Stainless Steel 317L Short and Long Radius Elbows Dimensions

| Nominal Pipe Size (inches) |

Outside Diameter | 45°Elbows | 90° Elbows | 180° Returns | ||||

| Long Radius | Long Radius | Short Radius | Long Radius | |||||

| (mm) | (inches) | Center to Face (inches) |

Radius (inches) |

Center to Face (inches) |

Center to Face (inches) |

Center to Center (inches) |

Back to face (inches) |

|

| 1 | 33.4 | 1.315 | 7/8 | 1 1/2 | 1 | 3 | 2 3/16 | |

| 1/2 | 21.3 | 0.840 | 5/8 | 1 1/2 | – | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 7/16 | 1 1/8 | – | 2 1/4 | 1 11/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 | 1 7/8 | 1 1/4 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 1 1/8 | 3 | 2 1/4 | 1 1/2 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 1 3/8 | 4 | 3 | 2 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 1 3/4 | 5 | 3 3/4 | 2 1/2 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 2 | 6 | 4 1/2 | 3 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 2 1/4 | 7 | 5 1/4 | 3 1/2 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 2 1/2 | 8 | 6 | 4 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 3 1/8 | 10 | 7 1/2 | 5 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 3 3/4 | 12 | 9 | 6 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 5 | 12 | 12 | 8 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 6 1/4 | 15 | 15 | 10 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 7 1/2 | 18 | 18 | 12 | 36 | 24 3/8 |

SS 317L Tee & Cap Dimensions

| Nominal Pipe Size (inches) |

Outside Diameter |

Caps | Straight Crosses | Straight Tees | Stub Ends | |||

| (mm) | (inches) | Length (inches) |

Center to End (inches) |

Center to End (inches) |

Lap Diameter (inches) |

Long Length (inches) |

Short Length (inches) |

|

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1/2 | 21.3 | 0.840 | 1 | – | 1 | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | – | 1 1/8 | 1 11/16 | 3 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

317L Stainless Steel Buttweld Fittings Weights(Kg)

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| 90° Elbow | 45° Elbow | Equal tee | 90° Elbow | 45° Elbow | Equal tee | 90° Elbow | 45° Elbow | Equal tee | |

| 8 | 0.02 | 0.01 | 0.03 | 0.03 | 0.02 | 0.06 | 0.04 | 0.03 | 0.07 |

| 10 | 0.03 | 0.02 | 0.05 | 0.03 | 0.02 | 0.03 | 0.06 | 0.04 | 0.09 |

| 15 | 0.06 | 0.03 | 0.09 | 0.08 | 0.04 | 0.10 | 0.10 | 0.05 | 0.14 |

| 20 | 0.07 | 0.03 | 0.13 | 0.08 | 0.04 | 0.17 | 0.11 | 0.05 | 0.20 |

| 25 | 0.14 | 0.08 | 0.28 | 0.15 | 0.11 | 0.29 | 0.22 | 0.14 | 0.38 |

| 32 | 0.23 | 0.11 | 0.49 | 0.26 | 0.17 | 0.59 | 0.40 | 0.23 | 0.68 |

| 40 | 0.30 | 0.17 | 0.68 | 0.40 | 0.23 | 0.86 | 0.51 | 0.29 | 1.02 |

| 50 | 0.50 | 0.25 | 0.85 | 0.70 | 0.4 | 1.28 | 0.91 | 0.59 | 1.59 |

| 65 | 0.85 | 0.48 | 1.41 | 1.40 | 0.77 | 2.19 | 1.81 | 0.99 | 3.13 |

| 80 | 1.25 | 0.63 | 1.77 | 2.20 | 1.08 | 3.31 | 2.97 | 1.50 | 4.45 |

| 90 | 1.70 | 0.75 | 2.67 | 2.83 | 1.42 | 4.08 | 4.00 | 2.00 | 5.44 |

| 100 | 2.10 | 1.08 | 3.46 | 4.47 | 2.09 | 5.27 | 6.18 | 2.81 | 7.71 |

| 150 | 5.45 | 2.72 | 8.07 | 10.89 | 5.44 | 10.99 | 16.32 | 8.16 | 13.61 |

| 200 | 10.20 | 5.33 | 15.65 | 21.54 | 10.77 | 20.91 | 33.11 | 16.56 | 28.12 |

| 250 | 18.15 | 9.75 | 26.46 | 38.56 | 19.27 | 35.38 | 51.71 | 25.86 | 49.90 |

| 300 | 25.80 | 13.62 | 39.46 | 59.42 | 29.71 | 62.14 | 79.38 | 39.69 | 83.91 |

| Product range and theoretical weights (kg) | |||||||||

| DN | Schedule 10S | Schedule 40S | Schedule 80S | ||||||

| Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | Con reducer | Ecc reducer | Reducing tee | |

| 40x.25 | 0.19 | 0.19 | 0.60 | 0.26 | 0.26 | 0.76 | 0.34 | 0.34 | 0.90 |

| 50x25 | 0.28 | 0.28 | 0.73 | 0.40 | 0.40 | 1.10 | 0.54 | 0.54 | 1.37 |

| 50x40 | 0.31 | 0.31 | 0.76 | 0.45 | 0.45 | 1.15 | 0.59 | 0.59 | 1.43 |

| 80x.50 | 0.55 | 0.55 | 1.56 | 1.00 | 1.00 | 2.91 | 1.79 | 1.79 | 3.91 |

| 100x50 | 0.78 | 0.78 | 2.94 | 1.50 | 1.50 | 4.48 | 1.95 | 1.95 | 6.55 |

| 100x80 | 0.87 | 0.87 | 3.04 | 1.74 | 1.74 | 4.64 | 2.33 | 2.33 | 6.79 |

| 150x80 | 1.82 | 1.82 | 6.86 | 3.95 | 3.95 | 9.68 | 5.51 | 5.51 | 11.57 |

| 150x100 | 1.96 | 1.96 | 7.10 | 4.07 | 4.07 | 11.94 | 5.96 | 5.96 | 11.97 |

| 200x100 | 3.01 | 3.01 | 13.46 | 6.55 | 6.55 | 17.98 | 9.23 | 9.23 | 24.18 |

| 200x150 | 3.19 | 3.19 | 14.08 | 6.74 | 6.74 | 18.82 | 10.12 | 10.12 | 25.31 |

Other Types of Grade 317L Stainless Steel Pipe Fittings in Stock

- Stainless Steel 317L Buttweld Elbow

- SS 317L Eccentric Reducer

- 317L SS Eccentric Reducer

- 317L Stainless Steel Reducer

- SS UNS S31703 Reducer

- SS WERKSTOFF NR. 1.4438 Pipe Fittings

- ASTM A403 WP 317L Stainless Steel Buttweld Fittings

- Stainless Steel 317L Concentric Reducer

- SS 317L 45° Elbow

- 317L SS 90° Elbow

- 317L Stainless Steel 180° Elbow

- SS UNS S31703 Equal Tee

- SS WERKSTOFF NR. 1.4438 Reducing Tee

- ANSI B16.9 WP 317L Stainless Steel Long Radius Elbow

- Stainless Steel 317L Lateral Tee

- Stainless Steel 317L Equal Tee

- Stainless Steel 317L Long Stub End

- SS 317L Stub End

- 317L SS Short Stub End

- 317L Stainless Steel Lap Joint Stub End

- 5" Nb Sch10s SS 317L 90° Short Radius Elbow

- 15 NB SCH 10 SS 317L 90° Short Radius Elbow

- SS 317L 1D Elbow/3D Elbow/5D Elbow

- 1/2” - 16” ASTM A403 WP317L Butt weld Elbow

- Stainless Steel 317L End Cap

- SS 317L Pipe End Cap

- 317L SS End Pipe Cap

- Stainless Steel 317L Bend

- SS 317L Pipe Bend

- 317L SS Equal Cross

- 317L Stainless Steel U Bend

- SS UNS S31703 5D Bend

- SS 317L 180D Bend

- SS WERKSTOFF NR. 1.4438 Short Radius Elbow

- ASTM A403 Stainless Steel 317L Unequal Tee

- Stainless Steel 317L Pipe Elbow

- SS 317L Long Radius Bend

- 317L SS Reducing Cross

- 317L Stainless Steel Straight Tees

- SS UNS S31703 Reducing Nipple

- SS WERKSTOFF NR. 1.4438 Barrel Nipple

- SS ASTM A403 WP317L 90° LR Elbow

- ASTM A403 Gr. 317L SS Piggable Bend

- ANSI B16.9 WP317L Stainless Steel 180° Return Bends

- SCH 60 317L Stainless Steel Pipe Nipples

- Schedule 80 SS 317L Grade Long Stub End

- DIN 2605 Stainless Steel 317L Elbow

- 317L SS Barrel Nipple